Color is a key indicator in quality control for clarified juices (such as apple juice and grape juice) due to their transparent properties. Stable color not only affects the sensory experience of consumers, but is also closely related to product consistency and market acceptance. The following is a technical method and practical recommendations based on transmission colorimetry, detailing how to ensure stable color for apple juice and grape juice.

.jpg)

1. The Basics of Color Measurement

Measurement method

Clarified juices are usually measured using the transmission method, which uses a spectrophotometer to measure the transmittance within the visible spectrum (400-700 nanometers).

Measurement process :

a. Sample preparation: Place clarified juice in a cuvette, making sure there are no bubbles or suspended matter.

b. Spectral Analysis: Record transmission spectrum data and calculate CIE Lab* or CIE XYZ color coordinates.

c. Standard Comparison: Compare measurement results to preset color standards such as the International Juice Federation IFU standard.

Applicability

Apple Juice: Target color is typically light yellow to amber, affected by oxidation and raw materials.

Grape Juice: Color ranges from light yellow to dark red, depending on the grape variety and processing.

2. How to Ensure the Color Stability of Juice?

Ensuring the color stability of juice requires comprehensive control of multiple aspects from raw material selection to packaging process, so as to significantly improve the color stability of juice and provide consumers with better quality products . At the same time, we recommend that in order to further improve the color stability of juice, advanced tools such as spectrophotometers, colorimeter and color matching software should be used to detect color data throughout the juice production process .

The following are specific measures:

First, in terms of raw material selection and control, fruit raw materials with stable color should be selected to reduce initial color difference. At the same time, during the production process, oxidation should be reduced by controlling the ambient temperature and oxygen concentration, thereby protecting the natural color of the juice.

Secondly, in the process of sulfur dioxide treatment and antioxidant use, the rational use of antioxidants (such as vitamin C) can effectively reduce browning. In addition, the amount and reaction time of juice clarifiers (such as pectinase, gelatin, etc.) should be strictly controlled to ensure uniform color of juice and avoid uneven color caused by improper treatment.

Finally, in the secondary sterilization and packaging process control stage, the use of ultra-high temperature instantaneous sterilization technology can reduce heat damage and avoid color degradation caused by high temperature. At the same time, choosing light-proof packaging materials (such as dark glass bottles or special film coating materials) can effectively block light, reduce pigment degradation, and maintain the color stability of the juice for a long time.

Spectrophotometers and colorimeter can provide the data needed for real-time monitoring and adjustment, while color matching software provides predictive insights for long-term color stability. The three work together to ensure that the juice has an attractive appearance when it is sold, and that it maintains its bright color throughout its shelf life, providing consumers with a consistent and high-quality product experience . By incorporating these tools into the production process, manufacturers can achieve more accurate color control.

3. Common Methods for Measuring Color of Clarified Juices

Instrumental measurement method ( spectrocolorimeter and colorimeter )

Color detection instruments , such as spectrophotometers and colorimeter, can play an important role in the entire process of juice production . In the raw material screening stage, by accurately measuring the color characteristics of fruits, it is possible to effectively screen high-quality raw materials with stable color and meeting standards, laying the foundation for subsequent production. During the processing process, these instruments continuously monitor the color changes of the juice, especially in key links that are prone to color shift (such as oxidation reactions, clarification treatments, and high-temperature sterilization stages), provide real-time data feedback, and guide producers to adjust the amount of antioxidants added or optimize process parameters in a timely manner to ensure uniform and stable color. For special categories such as clarified juice, professional model equipment can be used for precise testing. By quantitatively analyzing the changes in color values, a full-process color management system from production to storage can be established, thereby maintaining the visual quality of the juice during the shelf life.

The color of clarified juice can be measured by 3nh 's high-precision spectrocolorimeter and colorimeter , such as the YS series and NS series spectrocolorimeter provided by 3nh, which can accurately measure the color value of clarified juice. By measuring parameters such as CIELAB, Hunter Lab or color difference ΔE, the color change of juice can be quantified.

Commonly used measurement indicators:

L*: Lightness of juice

a*: the red-green axis of the color

b*: The yellow-blue axis of the color

ΔE: Color difference value, used to determine batch differences

Recommended equipment

3nh Benchtop Spectrophotometer TS8560

TS8560 desktop spectrophotometer has dual functions of transmission measurement and reflection measurement, and includes SCI/SCE (including specular reflection/excluding specular reflection) synthesis technology, supporting SCI+SCE simultaneous rapid measurement. Supporting two lighting modes, pulsed xenon lamp and LED, the repeatability of the reflectance chromaticity value of TS8560 desktop spectrophotometer is ΔE*ab ≤0.01, and the difference between units ΔE*ab is controlled within 0.1, and the data is stable and reliable. It complies with CIE No.15, GB/T 3978, GB 2893, GB/T 18833, ISO7724/1, ASTM E1164, DIN5033 Teil7, JIS Z8722 Condition C standards .

4. Color management system and quality control

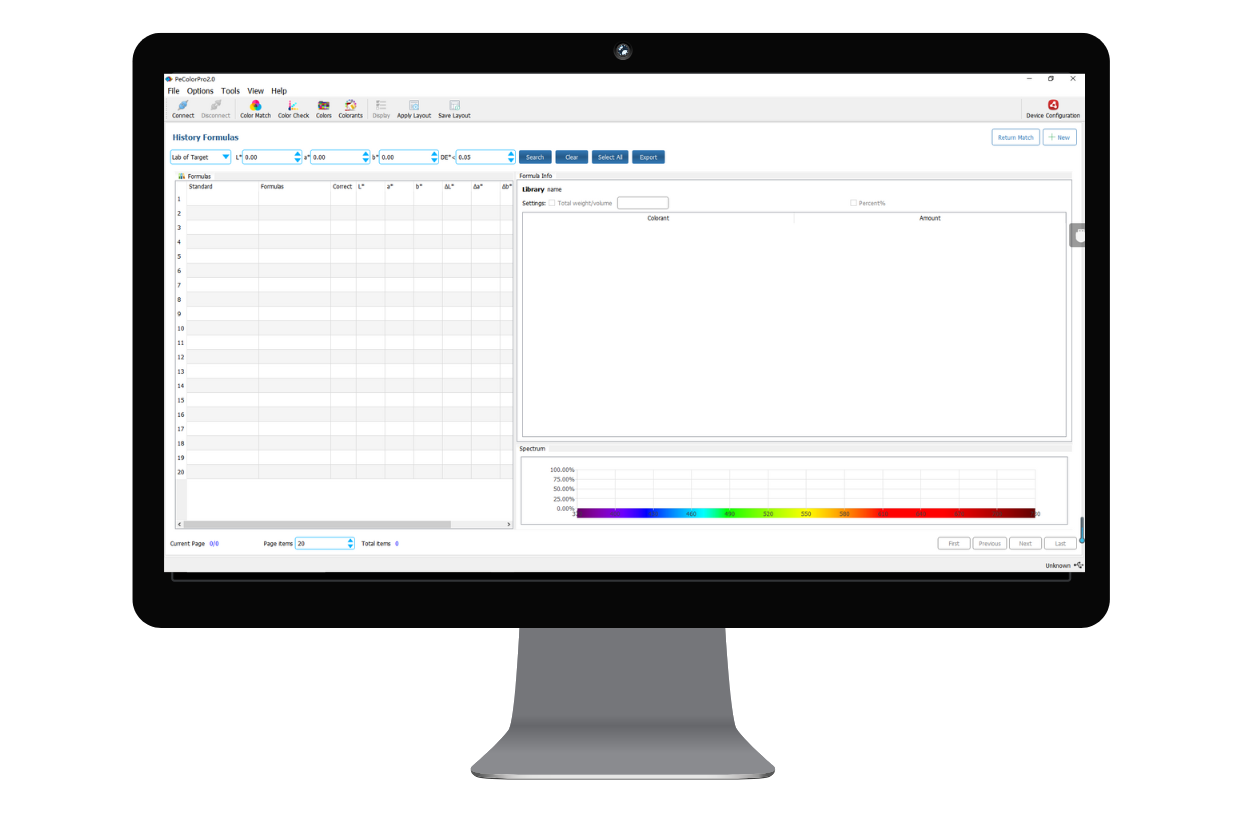

Use 3nh color management software PeColor to record and analyze juice color data and build a long-term stable database. Real-time monitoring of color fluctuations during the production process, timely adjustment of production processes, and ensuring color consistency of each batch.

Color matching software helps achieve the target color tone by predicting and adjusting the color formula. In the packaging stage, color matching software can simulate the effect of different packaging materials (such as glass or plastic, different color tones) on the influence of light, so as to select the packaging solution that best protects the color of the juice and slow down the color degradation caused by light.

PeColor Color Matching Software

PeColor color matching software is a color modulation software designed with operation as the orientation. It is suitable for color matching solutions for coatings, plastics, paints, inks and textiles, and can provide fast and accurate color analysis and formulations for various applications. PeColor has the characteristics of easy operation, accurate color matching and strong correction ability. It can be used not only for color matching in laboratories, but also for quality control and color difference correction in workshop production.

5. 3nh's advantages in the field of clarified juice color measurement

-

High precision and stability : ensure accurate and reliable measurement data.

-

Professional color management software PeColor : provides full-process color management solutions from raw material selection to finished product packaging.

-

Provide standard light boxes (TILO standard light boxes) to assist enterprises in visual comparison inspection to ensure product appearance quality.

In short, accurate color measurement and control can effectively solve the problem of color instability in clarified juice production. 3nh provides a comprehensive color measurement solution to help juice companies improve product competitiveness and win market recognition.

0086 18165740359

0086 18165740359

Skype Online

Skype Online