What is a Densitometer? How does a Densitometer work?

The working principle of a densitometer is based on the absorption and reflection characteristics of light. It is used to measure the optical density of the ink layer on the surface of a printed product, thereby determining the thickness of the ink layer. This measurement method is based on the fact that different colors of ink layers will react to light during the printing process. The reflection and absorption produce different effects. The following is a detailed introduction to the working principle of the Densitometer:

1. Principles of light absorption and reflection in Densitometers

The measurement principle of the densitometer is based on the absorption and reflection of different wavelengths of light on the printed surface. Usually, the densitometer emits white light to the printed surface, and the ink layer absorbs some wavelengths of light and reflects other wavelengths of light. This absorption is related to The proportion of reflection determines the density value of the ink layer.

Absorbance : The thicker the ink layer, the more light it absorbs and the less light it reflects, and the higher the density value.

Reflectivity : When the ink layer is thinner, it reflects more light and absorbs less light, and the density value will be lower.

Working principle of spectrodensitometer

Spectrodensitometer is a precision instrument used to measure the color density and color information of printed materials. It is widely used in the fields of printing and color management. Compared with traditional densitometers , spectrodensitometers can analyze color characteristics more accurately and comprehensively through spectrophotometry.

Spectroscopic densitometers use a spectroscopic device such as a grating or prism to decompose light into multiple wavelengths, and then measure the light reflection or transmission intensity of each wavelength. Unlike traditional densitometers that only measure overall reflectivity, spectroscopic densitometers can obtain complete spectral information.

In printing color measurement, the spectrodensitometer measures the light reflectance of different colors one by one to form a complete reflection spectrum. This method can measure the density of different colors more accurately, especially suitable for printing processes with high color reproduction requirements.

2. Light source and measurement angle

Densitometers usually have built-in light sources, commonly LED or tungsten lamps. These light sources are filtered through specific filters to obtain wavelengths suitable for measurement and illuminate the printed surface at a fixed angle (usually 45°). The sensor inside the densitometer receives the light reflected from the surface to measure the reflectivity and calculate the density value.

3. Application of densitometer filters

Traditional densitometers use different filters when measuring the density of different colors. For example, when measuring cyan, magenta, yellow, and black, filters that are complementary to the colors being measured are needed to filter out specific wavelengths, making the colors appear as black shades and making the measurement more accurate.

The use of different filters can ensure the measurement accuracy of the densitometer for each color, making it more able to reflect the actual ink layer thickness.

4. Calculation of density value

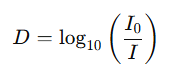

The Densitometer calculates the density value by the intensity of the received reflected light. The calculation formula of the density value is:

-

D is the density value ;

-

I0 is the incident light intensity ;

-

I is the reflected light intensity.

What can a Densitometer do? When should a Densitometer be used?

Today, densitometer calculations are being replaced by more comprehensive spectral data indicators. Most densitometers are spectral densitometers, although there are still some filter and LED based densitometers in use. Spectral densitometers may be able to better achieve state density than filter or LED densitometers. The following are the measurement functions that the 3nh YD50 series spectrodensitometer can achieve:

-

Density measurement : Densitometer is used to measure the density of different color ink layers on printed products to help control the depth of color and the thickness of the ink layer.

-

Tone Value and Tone Value Increase (TVI) : Densitometers can measure the dot area and its increase during the printing process. TVI (Tone Value Increase) is an important control parameter in the printing process to ensure color consistency.

-

Overprint control : The densitometer can measure the effect of overlapping ink layers of different colors to ensure accurate color superposition to avoid color deviation.

-

Printing contrast : Use a densitometer to measure the contrast value and the contrast of printed products to ensure the clarity of the visual effect of printed products.

-

Grayscale and hue errors : Densitometers can detect grayscale and hue errors in printing, helping to control the accuracy of neutral tones and maintain gray balance.

-

Printing plate measurement : The densitometer can also be used to measure printing plates. It is suitable for checking the density of printing plates before printing to ensure the quality of printing.

-

CMY balance and metamerism : Densitometers are used to measure the balance of CMY colors and detect the presence of metamerism to ensure color consistency across batches of printed products.

The powerful 3nh grating spectrodensitometer can adapt to a variety of application scenarios and is widely used in the ink printing industry, papermaking industry, coating industry, scientific research institutions, quality inspection institutions, and laboratory fields.

especially suitable for use in the following situations:

Printing process control: During the printing process, it is used to monitor the density of the ink layer in real time to ensure the color consistency of batches of printed products.

Printing quality inspection: Density inspection is performed before printed products leave the factory to ensure that the finished products meet color standards.

Prepress Inspection and Calibration: Calibrate plates and machine settings before printing to reduce scrap due to color differences.

Color management and matching: Match colors between multiple printed materials to ensure consistent color effects across batches and materials.

Importance of Densitometer

Densitometers are crucial in printing and color management. They ensure high-quality output of printed products by accurately controlling factors such as ink layer thickness, color consistency, and dot gain, effectively improving production efficiency and reducing scrap rates. Densitometers help achieve brand color consistency and are suitable for a variety of printing processes , such as offset printing, flexographic printing, and gravure printing , and promote the digitalization and automation of the printing process. As a core quality control tool in the printing industry, densitometers not only reduce human errors, but also support standardized color management, providing a strong guarantee for corporate cost savings and brand consistency.

0086 18165740359

0086 18165740359 Skype Online

Skype Online